CONTINUOUS LIQUID DOSING

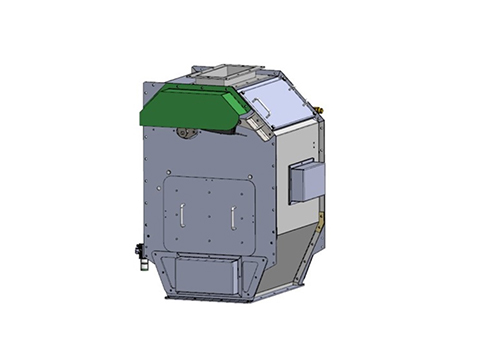

The system is a post pelleting liquid application (PPLA) system. It enables the feed manufactures to add liquid products into the feed which is difficult to add before or during pelleting because of their sensitivity to high temperatures or their negative impact on the pelleting process, liquids like enzymes, vitamins, flavors, sweeteners, fat/oil.

Feed Flow Control

Solid flow measurement utilizes mass-flow technology that eliminates the concern of changing feed densities. Actual weight readings of the feed are utilized to control the system, which ensures accurate and precise application of the feed to formulation.

Liquid Control

The system uses two liquid metering methods, loss-in-weigh and flowmeter, to double check liquid usage. Real-time weight processing and inventory is easier to reconcile by weight.

The system is controlled automatically by PLC and operated by PC SCADA or touchscreen panel with real time graphic flow. System provides trend curves and comprehensive usage reports exportable to USB driver. It is an open system which is ready for linking with feed milling automation system.